Some pics in the dark, with the projector turned on, showing the secondary monitor:

Lonherz Kernel – Project Log

- Purchasing the polycarbonate

- Beginning the making of touch sensors’ circuit

- Cutting the polycarbonate panel

- Making the structural joints

- Polishing edges of the panels

- Assembling the outer chassis

- Making the touch sensors

- Making the sensor circuit chassis

- Engraving the sensor circuit chassis

- Starting the motherboard structure

- Mounting the circuit chassis in the case

- Bending the motherboard structure

- Hard disk structure

- Engraving the hard disk structure

- Self-supporting structure of the motherboard

- Finishing the hard disk structure

- Optical drive structure

- VIDEO of the optical drive opening mechanism

- Engraving the Tron disc (optical drive structure)

- Mounting the optical drive structure

- Drawing the motherboard engraving

- Completing the touch sensors circuit

- Feedback LEDs bar for the touch sensors

- VIDEO and photos testing the touch sensors and their feedback LEDs

- Engraving the motherboard structure

- Engraving of the proximity sensor panel

- Making the actual proximity sensor

- VIDEO test of the proximity sensor

- Making and bending the psu cover

- Assembling all the chassis components

- Mounting touch sensors, circuit and feedback LEDs

- Mounting a mirror in the case

- Mounting the video projector in the case

- Making the cable that links the sensors circuit to all the case devices

- Starting to assemble the PC hardware in the case

- Assembling the PC and case lightings

- Extensions to the USB, ethernet and audio ports

- Mounting the fans

- Photos of the assembled computer

- Painting and mounting the case feet

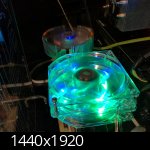

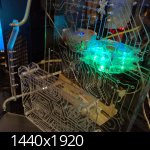

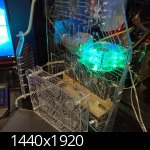

- Photos in the dark with projected secondary monitor

- VIDEO of the case’s features

- Mounting 4 other cold cathode lights

- Making a projection panel in polycarbonate

- Making the “prankster bit”

- VIDEO of the moving “prankster bit”

- FINAL PHOTOS OF THE KERNEL 1.0 (old version of 2009)

- 10 YEARS LATER… Lonherz Kernel 2.0

- Disassembling and cleaning the case

- Making a custom circuit for Arduino

- Replacing the Prankster bit motor

- Completing the Arduino circuit and the washing

- Cutting holes in the base for the cable management

- Mounting the LED strips on the engraved panels

- Arduino encasing structure

- Lighted border of the steel base

- Interspace for the cables and reassembling the case

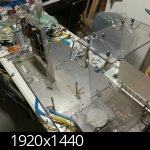

- Assembling the PC hardware in the case

- Some final works and inauguration

- FINAL VIDEO AND PHOTOS OF THE KERNEL 2.0