Now I began to mount the outer chassis, using the joints that i have made above.

Mounting the panels with tape:

Once that I have taken measures, I needed holes on the top of the tower, for mounting the joints:

The roof of the tower is mounted:

And now, the part of case placed behind monitor.

A special joint:

Then I fixed the top at the end of the right panel (the panel without protective film):

And then the panels of the left tower, using the special joint:

Then I taken other measures, I made some holes, etc…

I mounted the two parallelogram shaped panels:

Two details of the transparent panel:

I started to mount the chassis on the stainless steel base, always using the same joints.

I’ve made other joints (and I fixed them on the base)

I Began to mount these panels:

I begin to mount the panels of the section placed behind the screen:

And here I mounted the last panel (the one without white film):

Here you should see that there is a small gap between the base and the panels:

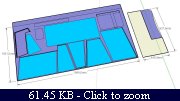

And this is the completed outer chassis:

Some better photos of the outer chassis: